Image courtesy of www.steel-vintage.com

History

Campagnolo Super Record was released in 1974 as the successor to it’s top tier component group Nuovo Record. According to the 1982 Campagnolo catalogue, the Super Record group could be ordered with either a Nuovo Record bottom bracket (steel cups and axle) or with a Super Record bottom bracket that featured aluminium cups and a titanium axle to save weight. Both steel and titanium axles shared an identical square taper design with threaded holes on each end. Bolts were used to fix cranks to the axle.

Unfortunately, this new titanium axle was not able to withstand the forces generated at the crank and was subsequently prone to breaking at the point where it attaches to the crank. This famously happened to 1982 Giro d’Italia, race leader Laurent Fignon who had a bad crash thanks to a broken first generation Super Record axle.

Redesigned Titanium Bottom Bracket Axle

Nuts are used to secure the cranks. No hollow ends.

In order to solve this problem, Campagnolo redesigned the titanium axle to use nuts instead of bolts for securing the cranks to the axle. This meant that the threaded hole was no longer required in the axle and thereby eliminating the original design flaw. You will see that both versions feature steel bearing races pressed onto the titanium axle to provide a durable contact point with the bottom bracket bearings. This titanium 70-SS axle (117 grams) is about 25% lighter than the equivalent steel Record axle (158 grams). Note: these weights do not include the required washers, nuts or bolts. The total weight of the Super Record bottom bracket is approx 205 grams vs. 285 grams for the Record bottom bracket. This bottom bracket was not mentioned in the 1985 Campagnolo catalogue.

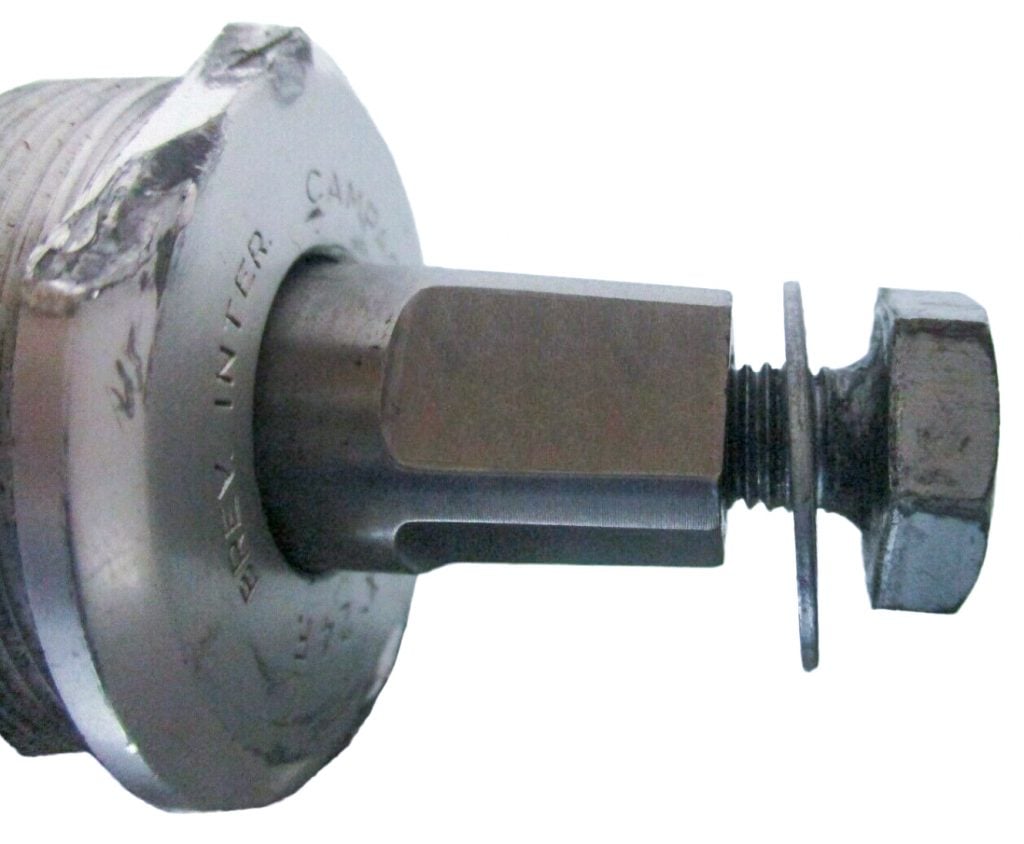

Problem with Lightweight Aluminium Cups

Unfortunately, lightweight aluminium cups do not offer the durability of traditional and cheaper steel cups. As you can see in the image below, the right side cup is easily damaged or rounded-off. This is a common occurrence for Italian threaded frames that require the right cup to be very tight. Using a good quality tool to install and remove this cup is imperative.

Specifications

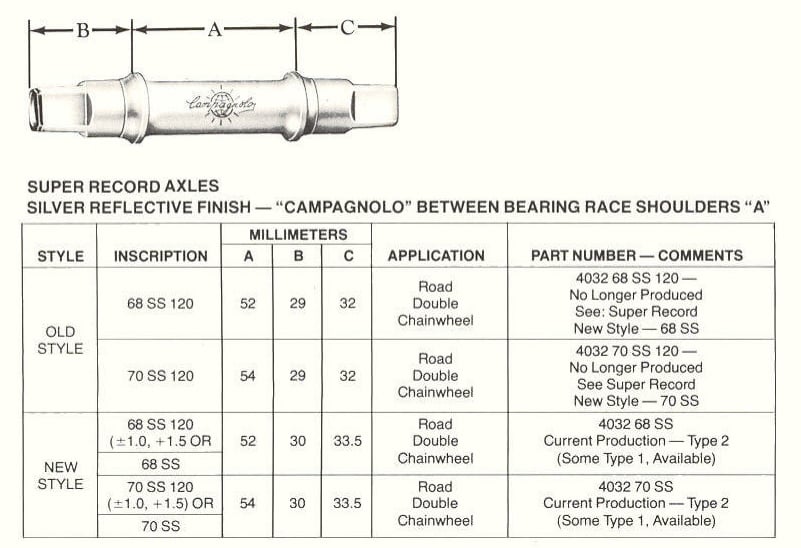

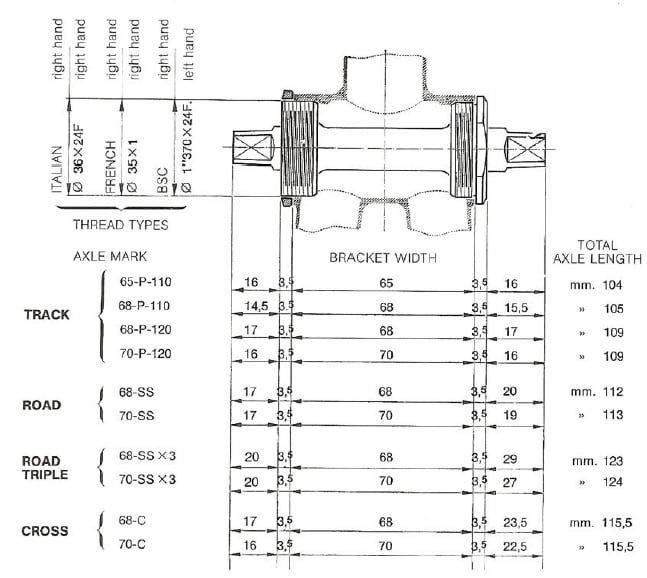

Campagnolo produced a range of bottom brackets to suit different frame bottom bracket shell diameters and threading standards. The axle also varied in dimensions to suit either track or road bikes. As this series of articles is focused on Super Record group for road bikes, I have not included bottom bracket specs for track bikes.

Bottom Bracket Width

Super Record bottom bracket axles were available in 2 different lengths to suit road bike frames with either 68mm or 70mm wide bottom bracket shells.

Ball Bearings

The Super Record bottom bracket features one pair of caged bearings (3/16″ bearings x 14pcs). The more common Record bottom bracket featuresone pair of caged bearings (1/4″ bearings x 11pcs). The bearings may not be caged in older bottom brackets.

Bottom Bracket Cup Threads

The bottom bracket cups were available in 4 different thread standards to suit the bottom brackets of a variety of different frames.

| Standard English French Italian Swiss | Thread 1.370″ x 24 TPI 35mm x 1.0mm 36mm x 24 TPI 35mm x 1.0mm | Left Cup RH thread RH thread RH thread RH thread | Right Cup LH thread RH thread RH thread LH thread |

Notes:

1. Left cup is only threaded into the frame as far as required to set the correct amount of load on the bottom bracket bearings.

2. Right cup is threaded all the way into the frame (on the drive side).

3. RH thread = turn clockwise to tighten.

4. LH thread = turn anti-clockwise to tighten.

5. Right cup with RH threads is prone to coming loose over time. This is due to the bearings rotating anti-clockwise in the cup (which can loosen the cup over time), hence the reason a LH thread was created.

Bottom Bracket Axle Length

Notes:

1. OLD STYLE axles are designated with a ‘120’ suffix. These axles are designed for use with a rear hub that is 120mm wide (measured from axle lock nut to lock nut). NEW STYLE axles that are not designated ‘120’ are for use with 5/6/7 speed clusters.

2. The first number ie. 68 or 70 is the frame bottom bracket width.

3. Axles marked SS (Serie Strada) are designed for use on road bikes.

4. The ‘+1.0, +1.5’ markings indicate the amount (in mm) the axle was lengthened on each side. In 1978 the CPSC (Consumer Product Safety Commission) set out requirements for the front derailleur to have a lip. In order for the crank spider and arm to clear the new front derailleur lip, the bottom bracket axle length was lengthened by 2.5mm overall.

5. Super Record Type 1 axle is the original hollow titanium axle design that uses crank fixing bolts. Super Record Type 2 axle is the improved titanium axle that uses crank fixing nuts.

Campagnolo Record Bottom Bracket

Out of interest, I have included the specifications of all the Campagnolo Record bottom bracket varieties below. Interestingly I have a 70-SS Campagnolo Record axle and it measures 115.5mm in length. This axle works fine with a Super Record crankset on my 1984 Colnago Master. The weight of the Campagnolo Record bottom bracket is 285 grams (with steel cups and steel axle).

Interestingly, this measurement of 115.5mm is 2.5mm longer than the 113mm specified length of a Record axle (below) and 2mm shorter than the 117.5mm specified length of the Super Record 70-SS axle (above). Presumably these variations will slightly alter your chain line.

BB Installation Tips

I have written a complete article on how to install a vintage Campagnolo bottom bracket. In this article I demonstrate how to install a Campagnolo Record Italian bottom bracket into a Colnago Nuovo Mexico frame.

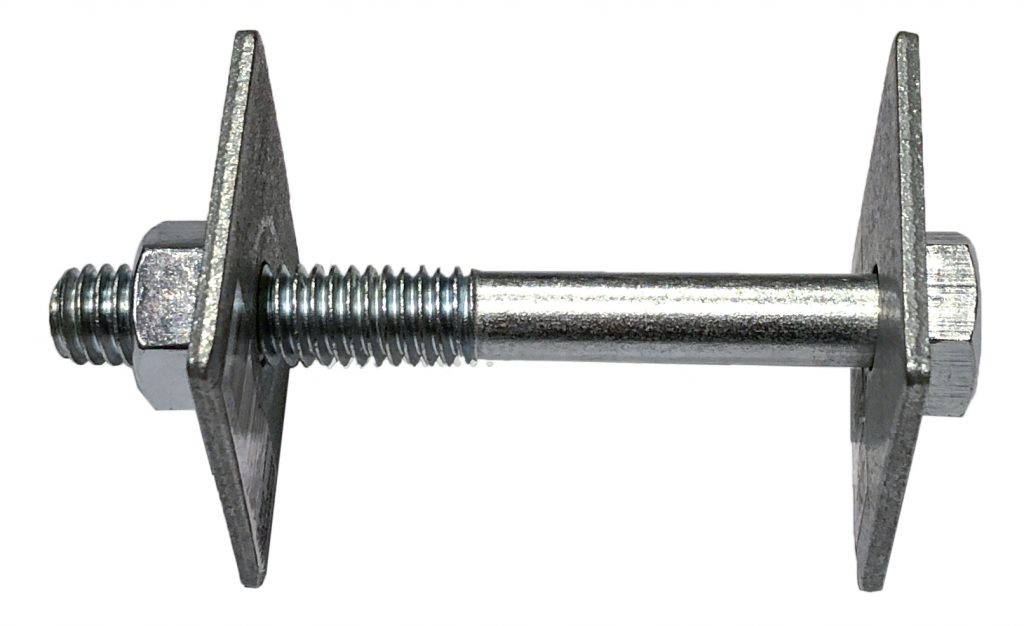

BB Removal Tips for Right Side Cup

Before you try removing the bottom bracket cups, remember the Super Record cups are made of aluminium and therefore much softer than the steel cups supplied in other groups. Due to their rarity, they are also valuable parts you don’t want to damage. Using high quality tools that fit perfectly is a good idea.

Tip 1. Removing the right BB cup from the frame can be very difficult. Most importantly you need to figure out which direction the cup must be turned to loosen it. Depending on the frame, this could be clockwise or anti-clockwise. It is also a good idea to secure your cup wrench tool onto the cup using a tool like the one shown here which is just built from parts available at your local hardware store.

- Get a bolt & nut plus 2 washers with specs like this;

- The bolt must be longer than the width of the frame BB shell. I use an M12 (1/2″) 100mm long bolt with matching nut.

- The washers must be a larger diameter than the frame BB shell. I use 2 x 50mm square washers to suit an M12 bolt.

- Now remove the left BB cup, bearings and axle from the frame.

- Place one washer against the end of the bolt.

- Pass the bolt through the open left side of the frame BB shell so that the threaded end of the bolt protrudes out of the hole in the right cup.

- Position the BB cup wrench tool onto the right cup.

- Place the second washer onto the bolt.

- Thread the nut onto the bolt until the washer prevents the BB tool sliding off the right cup. The nut must NOT be tight. Tighten just enough to keep the tool on the cup. If the nut is too tight it will prevent the cup from being loosened.

- Now try to loosen the cup by turning the tool in the correct direction. Once the cup starts to move, you may need to loosen the nut a bit more to allow the cup to keep unthreading. Continue until the cup is loose enough that you can remove the bolt and washers to full unthread the cup.

Tip 2. If the cup still won’t budge, you can try;

- using a rust penetrator like ‘Penetrine’

- a ‘breaker’ bar to give you more leverage.

- heating the BB cup to try to expand the threads in order to unbind them.

There is plenty of information on the internet using these methods. Hopefully a good quality grease and regular servicing will eliminate the need to take drastic measures.

UK Pricing in 1981

I found a 1981 catalogue for a British cycling shop with pricing as follows;

The Super Record titanium bottom bracket (v1) retails for GBP 72.45

The Record steel bottom brackets retails for GBP 22.90

Super Record Component Weight

I have weighed a set of Super Record components and quite surprisingly, these vintage parts compares quite favourably against the weight of a modern Campagnolo Super Record group set.

Learn more about Campagnolo Super Record

This article is just a small part of my full review of Campagnolo Super Record groupset.

References

I hope you found this article interesting. I have listed the following website pages as general references.

https://road.cc/content/feature/190040-retro-shimano-and-campagnolos-greatest-design-blunders

http://www.velo-retro.com/tline.html

Disclaimer!

Please remember that this information is only to be used as a guide.

I consider myself an enthusiast, not an expert. The information I have presented in this article is based on my many hours of online research.

Whilst I enjoy working on my own bikes, I am not a qualified bicycle mechanic. The content of this article is purely illustrative and does not constitute professional advice. For your own safety, any type of work should only be undertaken by a qualified bicycle mechanic. Incorrect assembly of parts could result in equipment damage, personal injury or death.

About Me.

I have been riding and working on my own bikes for many years now. I wanted to share my experiences, knowledge and research with others. My aim is to inspire people to get involved in all aspects of this amazing sport. Cheers.

Comments.

I welcome reader feedback in the comments section. Should you wish to suggest an amendment, please include a note advising the source of your information so that myself and other readers can ascertain the accuracy of your information. Note: Trolling or argumentative comments will be removed as they are counter-productive.

Thanks very much one of the most helpful and complete article I have ever read on bicycle maintenence. Please keep up the great work

Hi Wayne, thank for posting such a wonderful comment. It’s greatly appreciated!

Thank you very very much for that comprehensive article! I just bought a Super Record Type 2 Bottom Bracket with a BSA threading for my Hugo Rickert, but unfortunately the nuts, washers and the cages for the BBs are missing does anyone have an idea where I can get the nuts, washers and cages? Which threading is on the end of the axle? Thanks for helping me out.

Hi Thomas, Thanks for your comments. E-bay is probably the only option to find original parts but that would probably mean buying another BB set. It shouldn’t be too hard to find some suitable nuts and washers from a specialist bolt shop that will do the job. Similarly a bearing specialist my have what you need, otherwise the BB should still work fine with loose bearings. Just use a good helping of grease to hold the bearings in place during assembly. Make sure to use the correct qty and size of bearings in each cup. I think the cage just makes it easier and faster to assemble. There are plenty of wheel hubs and older BB’s that use loose ball bearings. Once assembled, everything stays in place. Just be careful when you pull it apart later not to lose any bearings.

Hi, very interesting series of articles. I’m an ‘aul fella’ now, but many years ago the last bike I raced was a Raleigh ‘team’ frame, built up with mostly Nouvo and Super Record components, apart from the chainset which I couldn’t afford at the time, so I fitted a cheaper Campag alternative. Flash forward over 30 years and I was out for a spin, when some smart alec commented on my mish mash of components (I think the seat post wasn’t to his liking either.

Anyway I managed to find a crankset, and then had to hunt for a BB set, as the more ‘modern’ Campag Bb was too narrow. Eventually I found one on eBay, and thanks to your measurement chart, all is good, and my bike is now (more or less) complete.

Here’s one for you, I bought (what I thought) was a second Super Record crankset, but which turned out to be what looks like a bastardised ‘track’ crank, with a second chainring on the inside, held in place by only the chainring bolts. There is no inner ‘step’ to locate the inner ring. What’s really odd about it, is rather than ‘Piste’ stamped on the inner face, it had ‘Strada’, but it’s definitely not a ‘double’ crank…… any ideas.

I can send photos if you like.

Hi Kevin. Thanks for posting a comment. That’s disappointing to hear that someone passed judgement on your pride and joy! But glad to hear you had success with a replacement BB. I didn’t really research the Campagnolo track cranks, but I wouldn’t expect them to be stamped Strada. Both my SR Strada cranks have an inner step to fit the small chain ring on the spider just like you mentioned. (For other readers) the spider is shown my article How to identify a Vintage Super Record Crankset. I would be interested to see a photo of the right crank arm (with the spider). Please post a link to the photos in the comments section.

Here’s a link to my Facebook page… a few (very few photos) Hope these help.

https://www.facebook.com/mag.mac.501/

Hi Kevin, link doesn’t seem to work.

It has been known for people to remove the inner ring shoulders to make the crank a Pista one. It would then still be marked Strata. Perhaps this has happened in this case?

By the way thanks for a great write up, with really useful information to help me replace my worn BB.

Hi Gareth, thanks for your contribution to the discussion and glad to hear the article was of help replacing that worn BB.

This is an invaluable website – all articles extremely detailed and helpful. As I am restoring a 1987 International from a bare frame without forks I shall be reading and hopefully digesting in order to get things right. (If you can put me in touch with any retailers who might sell vintage forks I would be more than grateful).

H Dick, thanks for your kind words. Great to hear that the information posted is helpful to you.

I’ve bought all my vintage parts on eBay as you can find things from all over the world. Hopefully you can find a set of Colnago forks for sale. Depending on how strict you are when restoring the frame, I think all the steel forks of that era had a 1 inch steerer tube diameter, so you could probably fit forks from other bike brands. Other options include buying another (cheaper) frame that is sold with suitable forks, doesn’t need to be an International as the different frames of the same era were often sold with the same set of forks.

If you get really stuck, I think you can order a set of brand new (modern) Colnago steel Precisa forks from a Colnago dealer as they are still making them for the modern Master and Arabesque frames, but they will have straight legs. More information about Precisa forks

Before you buy any forks, make sure the steerer tube is long enough for your frame size. Larger frames will need a longer steerer tube with a suitable amount of threads at the top. The headset will also need to match the thread standard of the fork, if you stick with Colnago forks, they should have Italian threading. Other brands may have British or French threading.

Best of luck with the build.

Hi R,

great stuff here, well done.

Wondering if you might tell what you know of Record, NR, etc. regular steel spindles.

I assume they are not all hollow but my experience is not vast. Have had plenty of them and many others apart but had not thought much about it until today when I was stripping a 1981 Bianchi Superleggera down to the bare frame for cleaning and evaluation. It had/has a standard NR BB where the SR may have been when it was new. I noticed the spindle is hollow so wondered if they are all so.

I realize I may be showing my ignorance here but that’s ok, the part of this that am an expert at is disassembly and reassembly with zero damage to parts, pieces, tools, frames, paint and flesh.

Tx, Van

Hi Van, thanks for your kind words. Sorry, unable to advise, I don’t have any broken axles to know if they are hollow on the inside, but I presume they are solid metal. I suspect many bikes with Super Record parts are fitted with the standard steel Record bottom bracket. This BB was cheaper and very reliable.

Tx for responding, maybe I’m more confused than normal but the axle/spindle in question is hollow/drilled all the way through the entire length, no breakage needed to see this, you can see all the way through from one side to the other.

Of course I can’t locate any of my others easily at the moment and if I’m honest I don’t have many, maybe half a dozen not in use.

Van

Hi Van, both my Campagnolo Record bottom brackets are assembled on bikes so I was unable to check, but after a bit of research, I found on page 6 of this article, it says that Campagnolo Gran Sport, Record and Nuovo Record bottom bracket axles are Type-1, Hollow with threaded ends to accept a bolt. Hopefully that answers your original question.

If I remember correctly, Fignon’s titanium bottom bracket spindle broke while on a lone breakaway in Blois-Chaville.

Hi James, yes that is correct, I mentioned that interesting fact in the second paragraph of the article. This was the reason for the redesign anf release of the v2 titanium spindle. Cheers.

Great article. Do you know how one should install the cranks on the titanium bottom bracket? normally no grease should be used (with a steel spindle) to avoid the cranks riding up on the shoulder of the taper. With titanium however, isn’t there the risk of the crankarms seizing on the taper and cold welding if anti-seize compound is not used?

Hi Marco, yes, I believe you make a good point. It is wise to use an anti-seize compound where titanium is in contact with alloy parts, particularly if you will not be disassembling the parts for long period of time, but lots of people have also said grease is fine as long as you do some kind of regular servicing (disassemble, clean and re-grease) on a regular basis. This forum has an interesting discussion in the topic

I may be going off the rails with the following question, but I’m hoping u may be able to help. I just bought some alloy cups that the seller stated were Super Record. They came with new bearings(11 balls) with resin retainer. The bearings don’t fit the cups. From what I learned from ur posts and some old Campy catalogs the alloy Super Record cups take 14 smaller ball bearings. I happen to have C-record bottom bracket on hand. That takes the smaller 14 ball bearings as well. The C-Record cups look identical to Super Record cups. Do you know if the alloy Super Record cups are identical to the C-Record cups? Seems like the axle length is the only difference between the two. Aside from the axle being titanium and requiring nuts of course. Any info would be much appreciated. Take Care

Hi Drew, I couldn’t find any part numbers for the alloy cups in my Campagnolo catalogs for comparison of Super Record to C-Record. I also do not have a C-Record bottom bracket, but it is quite possible the same cups are used in both.

I would measure the bearing size of the C-Record bottom bracket, if they are 3/16″ bearings x 14pcs then I would think they are probably the same cups. If you don’t want to use the C-Record bearings, it should be fairly easy to buy loose ball bearings of this size from a bearing supplier. I don’t think the cage is really required, it just helps to make everything easier to handle when working on the bottom bracket. Apply a fair bit of grease to hold the loose bearings in position for assembling the bottom bracket onto the bike. Good luck and let us know how you go.

A great article. The trick with the bolt and washers to help remove BB cups was passed on to me by my brother in law about 30years ago and works an absolute treat. Used it many times in the past 30yrs. I’ve just purchased a Super Record Titanium BB,Italian thread. Never had an Italian thread frame before so this should be fun. I found your comments on Italian BB very useful.

Hi Rhonda, glad to hear the article was helpful for you. Which Super Record BB did you get, 1st or 2nd generation? Here are some tips on installing an Italian Campagnolo Bottom Bracket. I used 50% loctite method on both of my Colnago’s and the right cup has not moved at all. Enjoy.

The specs you show for Record are for Pre-CPSC. The strada spindles get 1.5mm longer on drive side and 1 mm on NDS (as you say) and the overall lengths become 114.5 and 115.5 for BSC/French, and Italian. Bizarrely, Campagnolo shows the same outdated chart in catalog 18… which is from 1984 or so, YEARS after the CPSC changes.

The over-long dimensions for the titanium spindles make no sense to me. Campagnolo was able to make mistakes, but they were really good at getting final dimensions right, and were fussy (rightly) about chainline. I’d love to know what the 117.5mm dimension comes from. Not from a ti spindle that I’ve seen.

I recently bought a Colnago Super Profil 3 complete with Campy SR headset and SR bottom bracket. I tried fitting a 1970/80s Super Record crankset and found it didn’t clear the chainstay. BTW no issue with late 1980s Athena/Chorus cranksets. As mentioned in another comment re axles, I decided to replace the hollow titanium axle. I just removed it – without damaging those soft shells!! The axle, stamped 70 – SP measures 111mm and is symmetric, i.e., no long end for the chainwheels. Any ideas on this bb would be appreciated.

Best from Bavaria

Hi Colin, searching on Google for 70SP, apparently this bottom bracket is C-Record so maybe the C-Record crankset is designed differently than the old Record / SR cranksets.

I have 2 x 1980’s Colnago steel bikes, both with SR cranksets and both have a Campagnolo Record 70-SS bottom bracket axle, 115.5 mm axle length, Italian 36mm x 24F threads. Drive side is wider than non-drive side so no problem with clearance for chain rings. You should easily be able to find one of these or a compatible version to suit.

Hi Rouleur, Thanks, your efforts much appreciated. I too searched the net and came up with the C-Record which of course back then was made for new generation (C-Record, Chorus) cranksets. The axle is not magnetic and doesn’t have a brownish shimmer so definitely not titanium and being hollow, that is very good news indeed. I didn’t know Campy made hollow steel axles? Anyway, on with the rebuild.

Best Colin

Hi Colin, great, best of luck with the bike.

PS: Ital threading, stamped with the Campagnolo shield logo, weighs 142 g excl. cups and bolts. Looks very like the Campagnolo BB-01RE, Record, in VeloBase but that axle is steel and hardly hollow.

Fantastic site and info ,just revisited you to solve a thick/thin cup issue[thanks]and having recently seen the new LeMond documentary which albeit only for a few seconds contains footage of Fignons Blois tumble having only previously seen still shots ,it reminded me of your piece,it was my understanding it was the newly released 2nd gen titanium axle that broke ,the one with the threaded stud on the end which all makes sense .Campag had retrieved/taken back as many of these pretty new axles as possible asap once issues arose but Fignons bike got overlooked/forgotten as it wasn’t at the service de course the day the mechanics swapped axles over,they all remembered the moment he hit the asphalt I bet ,can I remember where I heard/read this ? of course not ha ha ,someone reckons in the LeMond film you can spot the bolt head but I was mesmerised by the crank still attached to his foot by the clip and strap